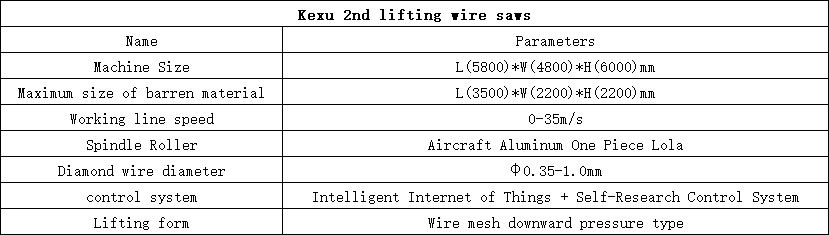

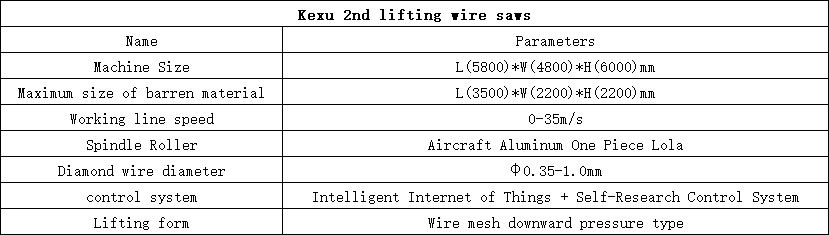

1. Cut large materials

The maximum stone size can reach 3600 * 2200 * 2200, with a width of 2.2 meters, making it easy to cut and assemble.

2. Good arrangementBidirectional full-size feeding, with feeding sizes of 2535 * 2830 and 4600 * 2570, facilitates the factory's renovation based on the original foundation.

3. Save spaceThe equipment size is 5.62 * 3.535 * 5.715, covering an area of 20 square meters. It does not require a dedicated electrical room and has a small footprint. More equipment can be installed in the original factory.

4. Cut fasterTo cut quickly, the stability of the wire mesh is the first element. Tension direct drive reduces the disturbance of the transmission mechanism in order to make the wire mesh stable and run faster!

5. Flat board surfaceThe board surface effect is good, which has been verified in 2024. High tension is the main reason, and the accuracy of the sunshine spindle and spindle hole processing equipment are important. The accuracy of the guide rail for lifting stones can ensure the stability of the lifted stones, which is ensured by the machine tool rather than manual adjustment.

6. Less problemsAccording to statistics, the best solution currently on the market is to replace 2 modules for about 20-30 stones, which affects the equipment's fault free time. We have designed a new cable servo electric cylinder and conducted harsh tests in the same environment, increasing its lifespan by 5 times.

7. Reduce consumablesUsing PTE material guide wheels, currently the guide wheels need to be replaced with a set of two sets of stones. Through our joint research and development with plastic rice manufacturers, the improved PTE technology has been compared and tested in the laboratory, and its lifespan is about twice that of the current polymer polyethylene guide wheels. Further on-site testing will be conducted.

8. Cut into light luxuryLarge storage line: 0.55 line stores 50000 meters, 0.6 line stores 4.3 meters,

Large winding motor: 100Nm servo motor,

Large diamond wire: 0.45mm baseline, 0.075mm steel powder, 2.25 times larger than 0.55 line diamond.

9. Long lifespanOver the past century, industrialization has proven that in order to achieve long-lasting high precision in large mechanical equipment, castings must be used. This is because wire saws have not been on the market for long enough to verify their advantages and disadvantages. However, we insist on an integrated full casting design. Currently, the market response has shown that non casting machine bodies cannot cut at high speeds like new machines, and cutting speed is slower than when new machines are used.

10. More energy-efficientThe common busbar, energy storage module, and main roller servo integrated machine are designed with water cooling, which reduces temperature and improves efficiency, saving about 5% energy compared to air cooling without energy storage.

11. More durableWater cooled all-in-one machine, free from dust, ensures the motor operates at its optimal state and is more durable.

12. Good managementCloud platform allows enterprise managers to access current production information, equipment information, historical records, etc. at any time.

13. Fast serviceBind WeChat to automatically push real-time notifications of faults or alarms.

14. Intelligent diagnosisBottom level development, full device sensing technology for water, electricity, gas, wire breakage, temperature, stone weight, etc., intelligent analysis, enabling automatic diagnosis and analysis of faults in the shortest possible time, timely maintenance of equipment, and production.