Home > About savch > News >

The warm spring breeze in Xiamen in March marks the grand opening of the 25th Xiamen International Stone Exhibition at the Xiamen International Convention and Exhibition Center! As a rising star in the field of stone equipment, Kexu Equipment, together with the fourth generation of lifting wire saw, made an amazing appearance in the outdoor W086 booth. On the first day of the exhibition, it signed a cooperation order with Türkiye's afyon KARAMEHMET company. The booth consulting customers are endless, and the real hard power lights up the exhibition!

Quanzhou Kexu Equipment Co., Ltd. is located in Licheng District, Quanzhou City, Fujian Province. It is a wholly-owned subsidiary of Sangchuan Electric Group. Based on Sangchuan Electric's over 20 years of experience in industrial automation, we focus on the stone industry and create a new intelligent equipment company to provide advanced and efficient complete equipment for the industry.

On the day of the exhibition, purchasers from China, Türkiye, Brazil, India and other countries crowded the 72 ㎡ booth. This is our third iteration of the product, which integrates and upgrades the entire electronic control system based on the previous generation of wire saws. Sales personnel from Kexu Equipment are demonstrating the operation of the equipment to customers using a touch screen, and the various data displayed have caused waves of astonishment.

Why did Kexu wire saw receive so much attention at the exhibition?

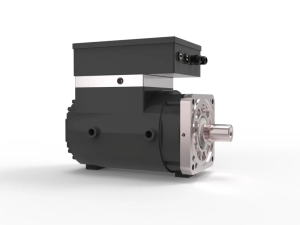

1、 Pure self-developed electronic control system

Based on the parent company's over 20 years of experience in electronic control development, unlike most competitors on the market who use ready-made servo motors, Kexu wire saw adopts a pure self-developed main roller water-cooled servo integrated machine, which integrates the servo and motor into one, with stronger anti-interference ability, faster communication speed, higher synchronicity, and more stable and reliable high-speed operation of the roller. The dual speed servo motor integrated machine with 1800rpm and 3000rpm provides strong support for efficient operation at linear speed.

2、 Self owned investment of millions of processing plants, integrated fully cast body

As is well known, wire saws generate vibration during operation, and conventional welding machines are prone to deformation, which affects the operating efficiency of the wire saw. Kexu Equipment has invested in five large gantry machining centers, which can be processed and formed in one go. The equipment is more sturdy and stable, ensuring long-term efficient and stable operation.

3、 Ultra high work efficiency

Kexu's fourth generation lifting wire saw has a working line speed of:

First gear: 0~1500m/min

Second gear: 1500~3000m/min

High quality spindle box supports greater tension (0-300N).

"I didn't expect the cutting efficiency of this equipment to be so amazing!" Mr. afyon, a customer from Türkiye, could not hide his excitement, while carefully recording the performance parameters of Kexu wire saw, he nodded and praised frequently.

As a senior practitioner in Türkiye's stone industry, he has heard about Kexu's equipment for a long time, but has never been able to visit the real machine in person. After gaining a deep understanding of the innovative technology and outstanding performance of the fourth generation lifting wire saw, he immediately made the decision and reached a strategic cooperation with Kexu on site, becoming one of the first international users of this revolutionary product.

On the afternoon of March 17th at 3:00 pm, Wang Hua'an from Sangchuan Electric provided a detailed explanation of Kexu's fourth generation lifting wire saw at the "Wire Saw New Product Launch Conference", which was unanimously recognized by the audience present!

Highlights:

→ Detailed explanation of the fourth generation lifting wire saw

→ 3D cutting animation demonstration

→ In depth interpretation by technical experts

The future development direction of wire saws

:676 Views